Langdale House - Wentworth Estate

Wentworth Estate

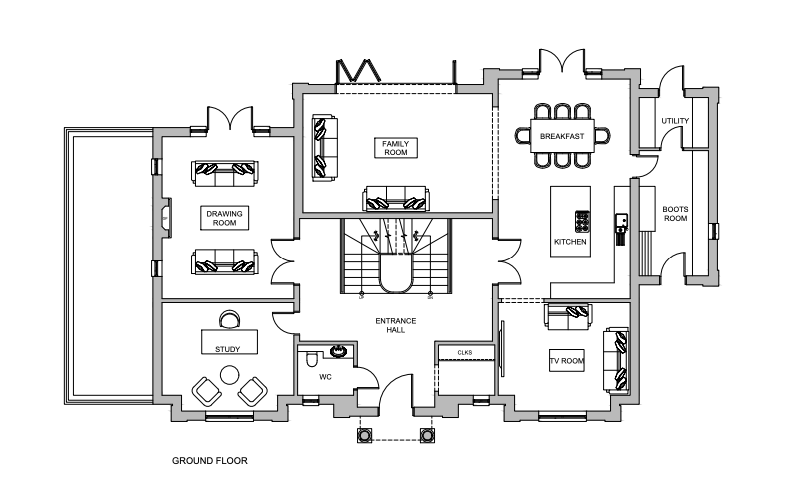

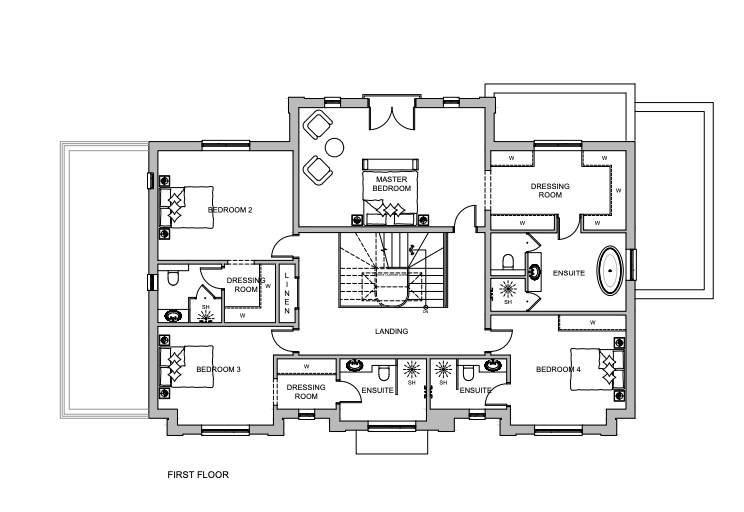

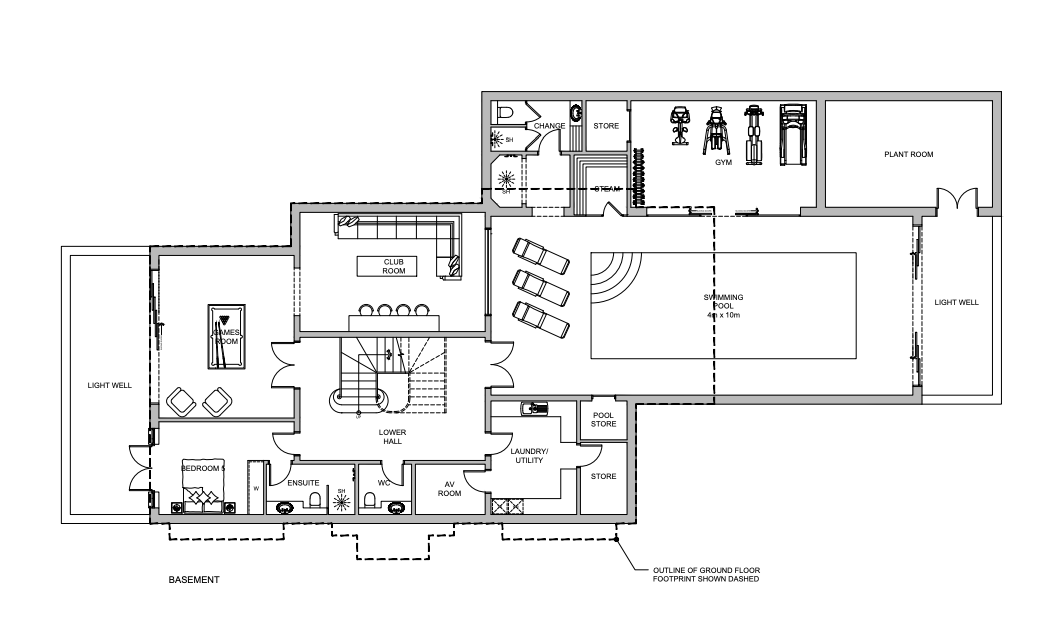

The property had been successfully acquired and planning permission secured for the construction of a lavish 12,000 square foot residence in one of the most prestigious estates in the United Kingdom. This project is a collaborative effort with Crown Designs. The acquisition of the property and the approval of the planning are critical milestones in this project, which allowed for the commencement of construction. The completion of this luxurious home will not only enhance the grandeur of the estate but also promises a substantial return on investment. Imagine descending into a sprawling basement that feels like a luxurious retreat. At the heart of this space is a shimmering swimming pool, perfect for a refreshing dip. Nearby, a sauna and hot tub offer ultimate relaxation, melting away the stresses of the day. For the sports enthusiast, a state-of-the-art golf simulator provides endless entertainment, while a fully equipped gym caters to all fitness needs. Movie nights are elevated in the private cinema, complete with plush seating and the latest technology. The bar area is ideal for social gatherings, stocked with a variety of beverages. Finally, a cozy library nook invites you to unwind with a good book, making this basement a haven of leisure and comfort. The basement construction process begins with excavation to a depth determined by the water table level, climate, and soil conditions at the site. The first step involves constructing piles to support the walls. These piles, typically made of poured concrete, bear the entire structure’s weight. Trenches are dug to accommodate the footings, which are usually twice the width of the walls and as deep as they are wide. Boards are placed in the trenches to form the wet concrete, which are removed once the concrete sets. Steel reinforcing bars (rebar) are embedded in the concrete to stabilise it during settling and mechanical vibration, which eliminates air pockets. Metal anchors are also embedded in the footings to secure the walls. Next, the basement (foundation) walls are erected. These walls must be strong, stable, and dry. Various materials can be used, each with different cost and performance factors. Poured concrete is ideal for overall strength—the thicker, the stronger. Concrete is poured inside forms, either wood or metal, with steel rebar embedded for reinforcement. Some forms include insulating features to help with temperature regulation. Poured concrete also provides a seamless, moisture-resistant barrier. The final step is constructing the slab, which forms the basement floor. The slab must be strong and level. A layer of leveling sand, usually at least 4 inches thick, is placed under the slab. The slab itself is typically at least 4 inches thick, flat, level, and dry. Depending on the climate and site conditions, additional modifications such as waterproofing membranes or insulation can be added to the exterior of the basement walls. Minimising moisture transfer is crucial in basement construction. Once the walls and slab are completed, the excavation site is backfilled up to the walls. This venture underscores the successful partnership with Crown Designs and the shared vision for creating a remarkable property.